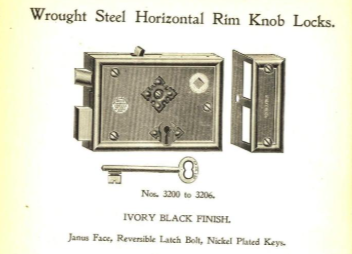

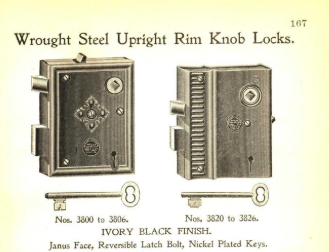

Rim Lock/ Carpenter Lock / External Mount Lock

This is an early type of door lock that is mounted to the exterior of the door with usually 3 long screws. Used most commonly between about 1850-1900, these types of door locks were made by most of the major manufacturers. There are two major types:

Horizontal mount and

Vertical/Upright mount

The placement of the doorknob hole (backset) and the keyhole can vary quite a bit on these types of locks, so be sure to measure where your holes are in your door. The good news is that the box covers a large area and the holes needed are very small, so if you need to make minor adjustments it can easily be covered or filled.

These locks were usually used with white, brown, black or swirled (Bennington style) enamel or metal doorknobs. One doorknob would have a flare at the base of the neck. This side goes against the lock. The other doorknob has a regular neck and was used either with a small rosette and keyhole cover or a door plate. Usually the two part rosette and keyhole cover were used with this type of lock because of the variation in doorknob and keyhole placement.

The strike plate for a rim lock is rectangular and mounts to the outside of the door frame with two long screws.

Most of these locks were made as reversable, so you can open up the box and flip the latch part to make it work for either a right swing or a left swing door. The most common setup has a latch for the doorknobs and a deadbolt which is operated with a skeleton key. Many of them also had an additional small latch lock feature where you can lock the latch part from the lock side of the door.

Most night latches are a type of rim lock.

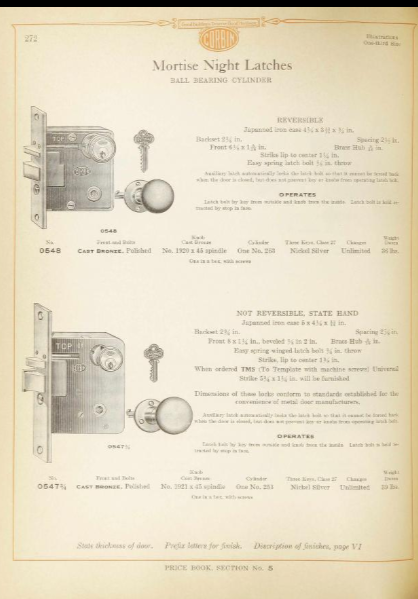

Rim Night Latch

The night latch is an additional security lock usually used on exterior or apartment doors. It was usually mounted above the doorknob. With the most common type, the lock part is mounted to the outside part of the door on the interior. The strike mounts to the outside of the door frame on the interior. These were usually smaller than a traditional rim lock. The interior latch part would have a twisting mechanism or thumbturn which operates the latch. The outside has a simple cylinder lock which takes a modern style key. The cylinder mounts through a small hole in the door and attaches into the back of the night latch.

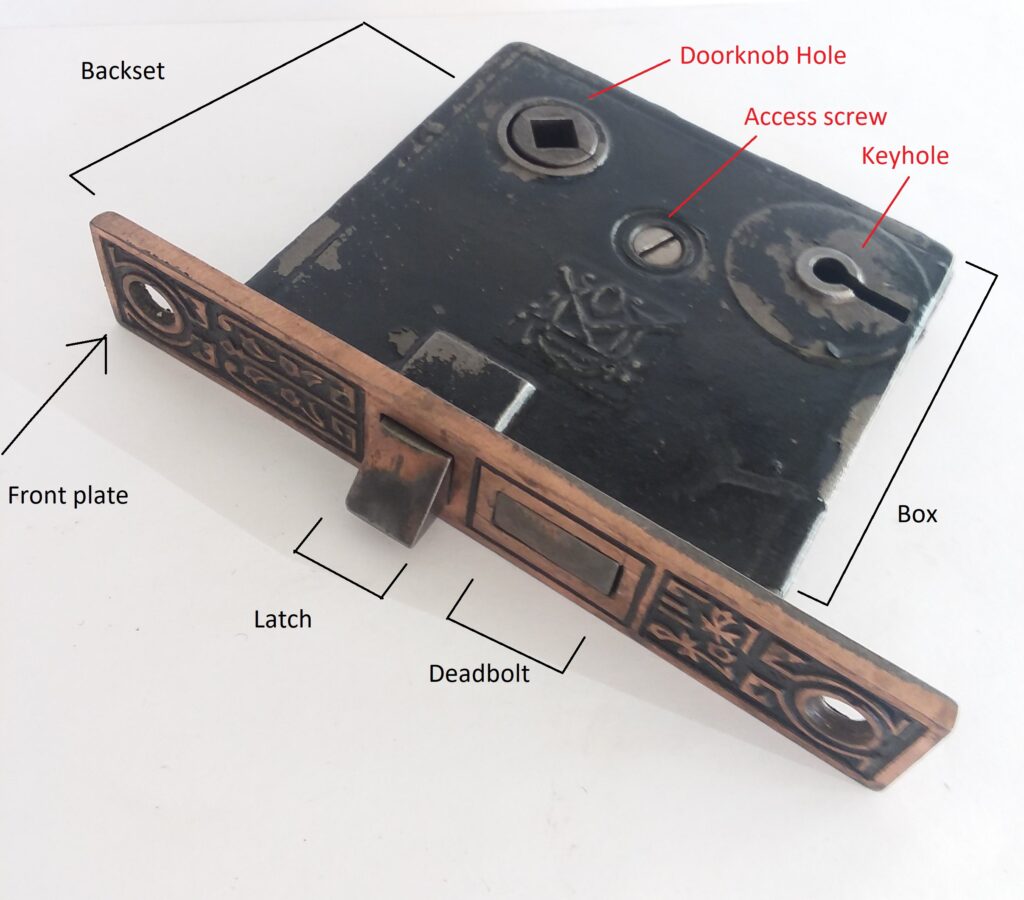

Mortise Lock

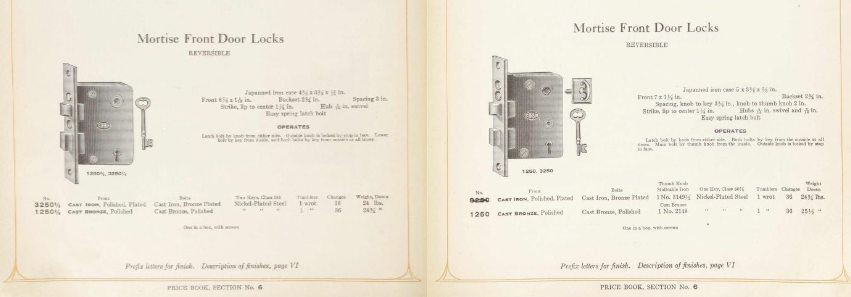

Mortise locks are named such because they fit into a large cutout (mortise) in the door. These were commonly used from about 1890- the 1940’s. The size of both the box part and the front face can vary quite a bit depending on what type of door they were made for, so it is important to measure both the cutout in the door and the cutout on the edge.

Most of these locks were made as reversable, so you can open up the box and flip the latch part to make it work for either a right swing or a left swing door. The most common setup has a latch for the doorknobs and a deadbolt which is operated with a skeleton key.

Mortise lock boxes made for interior doors are fairly standard and have minor variations- usually within about 1/2”. The distance between the doorknob hole and the keyhole is usually the same for interior mortise locks.

Mortise locks for exterior or commercial doors can vary quite a bit and the distances between the doorknob hole and keyhole also vary. There are also special mortise lock boxes that were made for screen doors or doors with large areas of glass where the wood frame is smaller. These can vary quite a bit in size, backset and doorknob hole-keyhole distance.

The most standard setup is one with a latch operated by the doorknobs and a deadbolt operated with a skeleton key. This takes a two hole strike plate that is attached to the door frame.

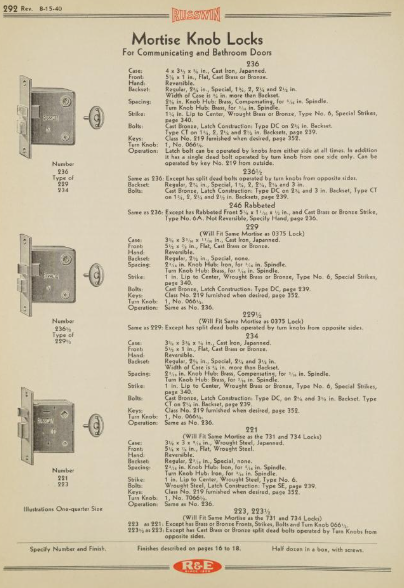

Other fairly common types of mortise locks are:

Exterior door lock boxes which are usually larger and often have a 2 push button function to lock the latch from one side.

Pocket door lock boxes with a push button and/or skeleton key latch function

Thumbturn locks with a thumb latch activating the deadbolt instead of a keyhole. Often the latch would be only used on one side. An example would be a bathroom door which can be locked from the inside, but not the outside. The distance between the doorknob hole and the latch hole was not always standard.

Small latch locks that do not have a deadbolt. These are similar to modern interior door latches, but are a bit larger.

French/glass/screen door locks. These were about half the depth of a standard lock box and were made to fit into smaller frames. They usually still have both the latch and deadbolt functionality.

Hotel/apartment locks. These are larger exterior boxes used for hotels or apartments. They have a two different keyholes which both work on the deadbolt. One would be for a universal landlord key and the other would be for the tenant key.

Thumb latch handle lock boxes have a bar at the bottom which is pushed up by the handle’s thumb latch

Mortise lock with cylinder- these have a large hole usually at the top for the addition of a cylinder lock which takes a flat type key instead of a skeleton key.

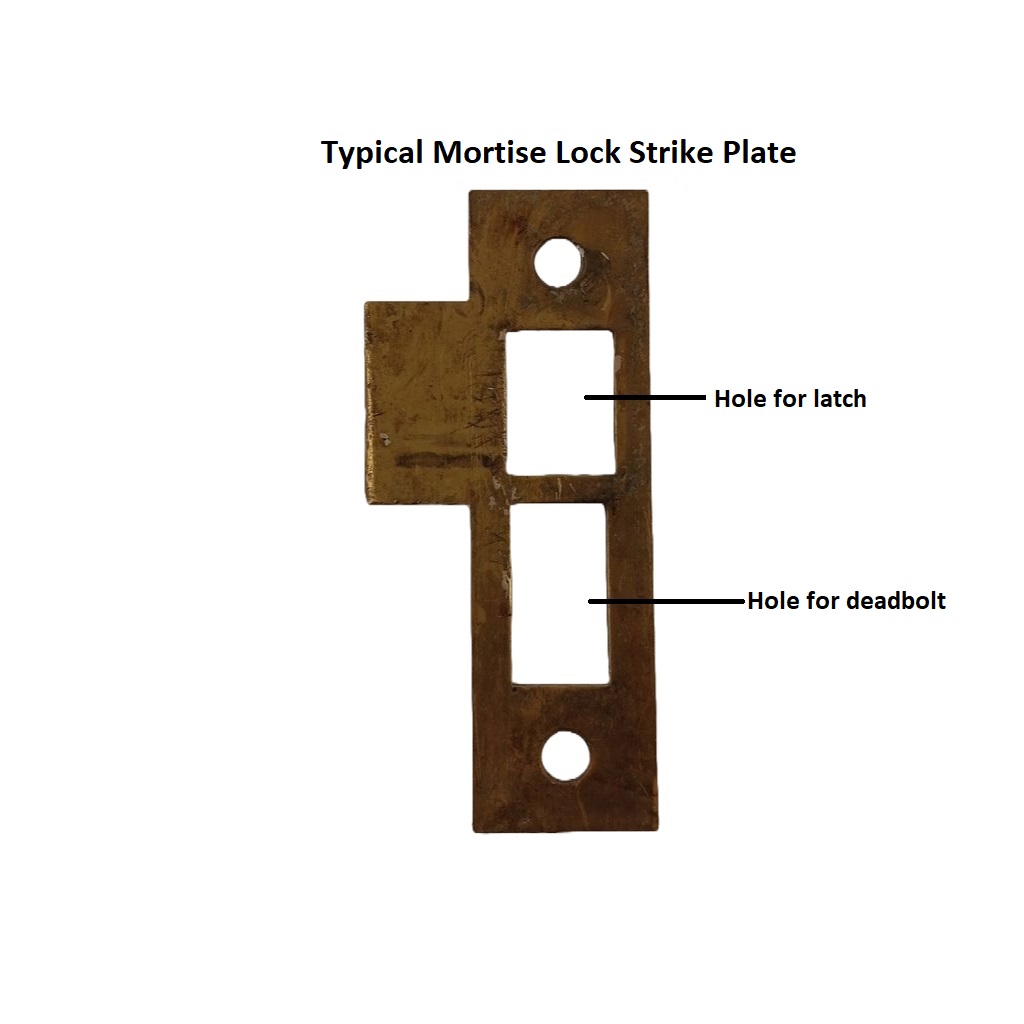

Strike Plate

A strike plate can refer to any metal piece that is used to protect a cutout in wood where a latch of some type fits in.

On doors, the strike plate is used with a lock of some type and is mounted to the frame of the door to protect the wood from being damaged and hold the latch/deadbolt of the lock securely in place. Strike plates for rim locks and latches mount to the exterior of the door frame. Strike plates for mortise locks mount inside the door frame and are inset into the frame. Modern strike plates are often just a single hole. Most antique strike plates for mortise locks have 2 holes.

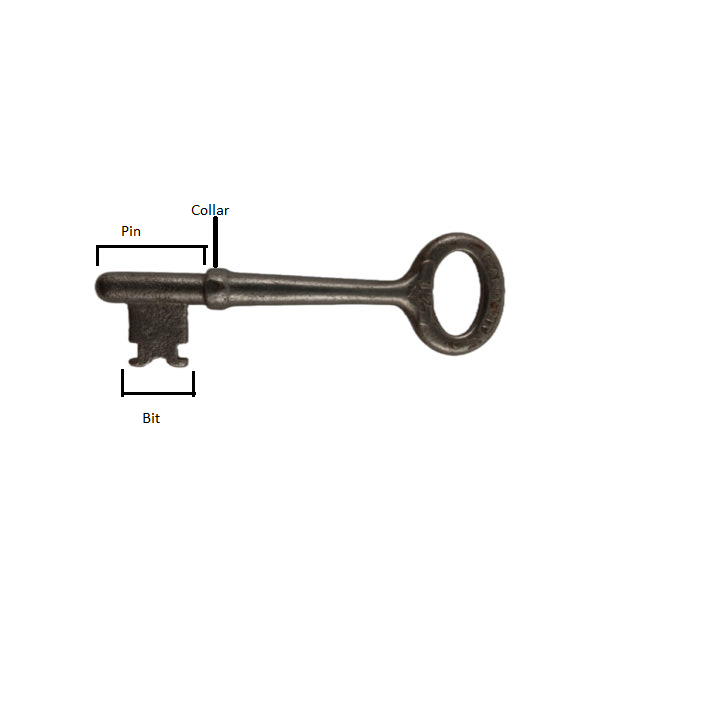

Skeleton Key

Skeleton keys are used for antique door, furniture or gate locks and differ from a modern style key in that the barrel is full round as opposed to flat. Door keys usually have a solid barrel while furniture and gate keys sometimes have a hollow barrel for a pin that extends from the lock.

Escutcheons

Escutcheons are any type of cover that goes on the outside of the door to protect the doorknob hole and keyhole. In the case of an externally mounting lock box, and escutchoen would be placed on the oposite side of the door to the lock box. In the case of mortise locks, an escutcheon would be places on each side of the door. There are three major types of escutcheons:

Rosette- a basic round cover that only covers the doorknob hole.

Keyhole cover or thumbturn latch- this would be used in conjunction with a rosette to protect the keyhole or latch hole. Smaller keyhole covers were also used on furniture pieces to protect the wood around the keyhole.

Door plate– this is a combined rosette and keyhole cover into one piece. Although the distance between the doorknob hole and keyhole tended to be fairly standard for interior doors, it can vary quite a bit for exterior doors or doors with latches instead of keyholes.

Pocket door plates are a bit different from standard door plates because they have to mount flush. They were made both with and without keyholes. A pocket door plate required cutting a bit more out of the door to fit the inset handhold. Some flush mount window sash lifts were used both for windows and pocket doors. A pocket door plate is great for the back of a barn door.

Door Hinges

Most older door hinges had either a ball finial or a more decorative finial end. More modern hinges tend to have a rounded cap and rounded corners. The two major types of door hinged are:

Surface mount- these are offset hinged where one end mounts to the front of the door and can be seen and the other end mounts into the door frame. The side that mounts to the outside of the door usually has a beveled or slightly decorative edge. The most typical size for interior doors is 3 1/2” with 3 holes. Larger doors or exterior doors may have had larger hinges with more holes. Very early doors (1800’s to very ealy 1900’s) sometimes had smaller hinges.

Mortise hinge- This is the most typical type of hinge that mounts into a small cutout on the side of the door and the other side mounts into a small cutout in the door frame. The most typical size for interior doors is 3 1/2” with 3 holes. Larger doors or exterior doors may have had larger hinges with more holes. Very early doors (1800’s to very ealy 1900’s) sometimes had smaller hinges.

Latch converter

This is a modern piece of hardware that fits into most standard modern door cutouts and allows an old square shaft doorknob to be used. Some are adjustable for different backsets and there are shorter ones out there for french doors and screen doors. This will allow you to use old hardware on a modern door without having to modify the door. Note that the modern hole through the door is 2 1/4”diam. Almost all antique rosettes and some of the older door plates are too small to cover this hole. You will need full sized door plates (2 1/4”w or more) on each side of the door in order for everything to function properly.

Doorknob Shaft/Spindle

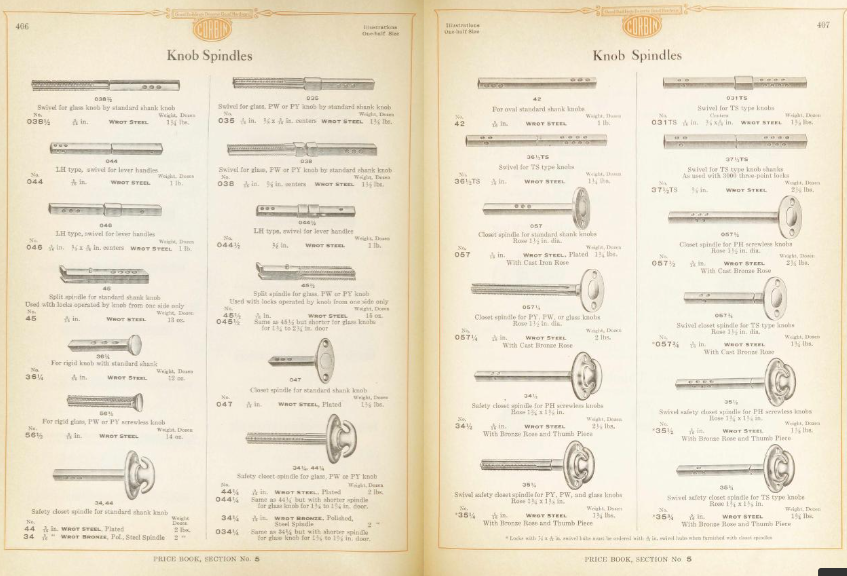

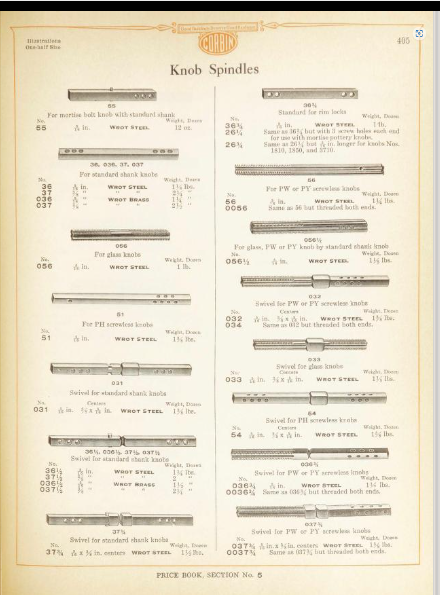

This is the piece that connects the two doorknobs and goes through the square hole in the lock box. Most were adjustable in some way to accommodate different thicknesses of doors. Minor adjustments can be made by adding small washers in between the door plate and the base of the doorknob.

The typical size for a doorknob shaft/spindle is 5/16”. Some exterior and commercial shafts were larger. Some screen door types were smaller. There are a few unique shafts out there that were introduced as innovations and used for only a few years. These include a variety of screwless shafts, shafts where a screw in the center of the doorknob would screw into the end and 3 part shafts held on one side by a pin. There were also a few companies that had their own ways of connecting things and whose hardware only works with their unique pieces. Two of those companies were Gilbert and Chicago Hardware.

The two main types of doorknob shaft spindles are threaded and non threaded. There were also combination shafts with ine threaded side and one non threaded side.

Threaded shafts can be squared or rounded and require the neck of the doornob to be threaded on the inside. They are held in place by a flat set screw that is threaded into a small hole on the side of the neck of the doorknob. That screw is tightened down to the flat part of the shaft. Threaded shafts allow a bit more adjustability than non threaded shafts.

Non threaded shaft/spindles are square with multiple holes on each end for adjustability. A small screw is threaded into the shaft through a small hole in the neck of the doorknob. Nonthreaded shafts are somewhat limited due to the number and spacing of the holes which varies. For oval doorknobs, sometimes the holes in the shaft had to be offset so that the oval would stand upright on each side.

There are longer and shorter versions of each type of shaft for different types of doors. There were also security options for exterior doors which used a pin through the shaf instead of a screw on the outside knob. Further security could be added by adding a swivel that works with single sided locking lock boxes.

The following images show the options from just one catalogue: